MAXIN JOINT®header CCH type is a header used for pipes for heating. The connection method with the heat source device uses a CCH clip. By combination with MAXIN JOINT®series, work efficiency is improved.

Header CCH type 4P

Header CCH type 2P

1.Realizing lighter weight

70% lighter than metal products. Improve work efficiency!

2.Foregoing the need for thermal-insulation material

Enhanced thermal insulation effect by special attributes of plastic

Simple design

3.Providing freeze-fracturing preventive function→Operating Manual Of Freeze-fracturing Preventive Function

The header is not broken even though the water inside is frozen.

4.Delivering CCH clip compatibility

Enable to attach to the heat source device with CCH clip

Header CCH Type(2P)

Header CCH Type(3P)

Header CCH Type(4P)

Header CCH Type(5P)

Header CCH Type(6P)

Added freeze-fracturing preventive function enables being used in cold areas.

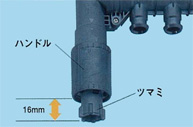

| (1) Ordinary use condition The product is delivered with a condition as shown by the photo to the right. |

|

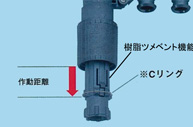

| (2) When the function was activated If the water being frozen inside, the knob moves downward and make the space inside to prevent the header from fracturing. *Please do not remove C ring. |

|

| (3) How to return to the original position After having confirmed the water inside is not frozen, push the knob up by hand. (You feel light click when completion.) Note 1) Please ensure that resetting is only completed by the person in charge. |

|

| Item | Specification | ||

|---|---|---|---|

| Strength of branch pipe | Strength when upward/downward load is applied to branch pipe with the condition of the header attached to heat source device. | N・cm | 1,600 or more |

| Drop test | Drop from a height of 1m to concrete surface | – | No problem with performance |

| Wheel operating torque | Operating torque at valve closure and opening by turning the wheel | N・cm | 70 or below |

| Wheel tolerable torque | Limit tolerable torque when turning the wheel | N・cm | 400 or below |

| Hydraulic pressure tolerance | Tolerable hydraulic pressure applied to inside of header | KPa | 290 or below |

| Pressure drop | Connect header to manometer to measure pressure drop by pressure gap at delivery of water (amount of water delivered: 4L/min) | KPa | 11 or below |

| Freezing test | Filling water inside the header and connecting pipe, and freezing in tightly-closed condition | – | No problem with performance |

| Cold-heat repetition test | Repeating 27,000 cycles of water delivery at temperatures 10℃(2.5min)⇔80℃(2.5min), to confirm the sealing properties | – | No water leakage |

| Weather-resistance test | Repeating weather-resistance test 3,000 Hrs, to confirm change in the strength | % | Strength reduction, 15 or below |

| Chemical-resistance test | Attaching test specimen on the 1/4 ellipsoidal jig, applying adhesive agent on the surface, to confirm for abnormalities | – | No problem with performance |

CCH straight male series , 7A, 10A and 13A, connect to the part for hot water. The female fitting is used for single heating system. Water stop cock is attached to heating/hot water area to stop water. These fittings are connected by CCH clips. These fittings offer lighter weight.

CCH fitting straight 7A

|

CCH fitting straight10A |

CCH fitting straight13A |

CCH fitting straight female |

CCH fitting straight water stop cock |

CCH fitting elbow 7A |

CCH fitting elbow 10A |

Application examples of each series

| No. | Item | Specification |

|---|---|---|

|

1 |

Main body material | Special PPS plastic |

| 2 | Main body material grade | NIXAM®1673 |

| 3 | Used O ring material | FKM made DAI-EL G701 (color tone: black or green) |

| 4 | Used medium | Tap water, antifreeze liquid |

| 5 | Used medium temperature | 80℃ (joint pipe material: cross-linking polyethylene, polybutene) |

| 6 | Used medium pressure | 0.49MPa (5kgf/cm2) or below |

| 7 | Main body heat-resistant hot-water temperature | 120℃ |

| 8 | Main body flammability | UL94-V0 equivalent |

| 9 | Surface hardness | 114 (Rockwell R scale) |

| 10 | Snap area insertion capacity | 147N (15kgf) or below |

| 11 | Snap area removal capacity | 294N (31kgf) or more |

| 12 | Cold-heat repetitious properties | No water leakage 15,000 cycles (with 80℃ tap water, hydraulic pressure 0.39Mpa; 2.5min)~(20℃; 2.5min) as one cycle |

| 13 | Continuous hot-water delivery properties | No water leakage (with 80℃ tap water, antifreeze liquid, hydraulic pressure 0.098MPa 17,500Hrs) |

| 14 | Adhesive agent tolerance | No cracks (500Hrs at 90℃ based on 1/4 Ellictip Curve Method) |

| 15 | Freeze tolerance | No water leakage (-17℃ after leaving 240Hrs. Leaving at normal temperature, hydraulic pressure 0.49Mpa) |

PAGE TOP

add_action( 'wp_footer', 'mycustom_wp_footer' ); function mycustom_wp_footer() { ?>